Zmodell ZM05A – the smallest digital decoder in the world

Aug 5, 2023 15:20:08 GMT -5

Kez, tjdreams, and 10 more like this

Post by scanrail on Aug 5, 2023 15:20:08 GMT -5

I would like to introduce my next development – ZM05A, the smallest digital decoder in the world currently existing on the market.

The background of this development was the fact that I was not satisfied with the limitations of small Doehler & Haass PD05A digital decoder which lack some crucial features presented in the next small decoder DH05C – like supporting analog mode by default, conditions, AUX outputs and some others. Replacing firmware by the one from D&H PD12A seemed to me not to be a convincing solution, as the only thing it did is adding support of analog mode (at the cost of some existing features of PD05A), while all other limitations common to PD series still remained. I admit that Doehler & Haass digital decoders are almost unknown in the USA, but I just thought that these details may be interesting for the whole story.

In the past, I widely used very small CT Elektronik DCX77z decoders for digitizing certain models in Z scale (in particular, steam locomotives which often offer very limited space inside for anything extra), but after CT Elektronik has been vanished from the market, D&H PD05A remained mostly the only possible option for such intricate digitizing projects.

It is also a well-known fact that CT Elektronik decoders were mostly a “wild, nasty and untamed” thing. Furthermore, they were prone to complete failure after a “single breath”. All this together unfortunately made them an unfavorable solution.

After successful development of a number of different digital decoders for Z scale locomotives (such as AZL SW1500, Märklin DB V80, VT98, SBB Ce 6/8 III and DB V188) using proven Doehler & Haass technology, and also using a different modification of microcontroller with reduced thickness (0.5 mm against 0.9 mm) in my digital decoder for Märklin DB V80 locomotive, I came up with an idea to develop an alternative to PD05A which would have nearly the same size, but no functional limitations at all. I decided to use 2-sided design and to populate all thinnest electronic components on one side of the circuit board and everything else on another.

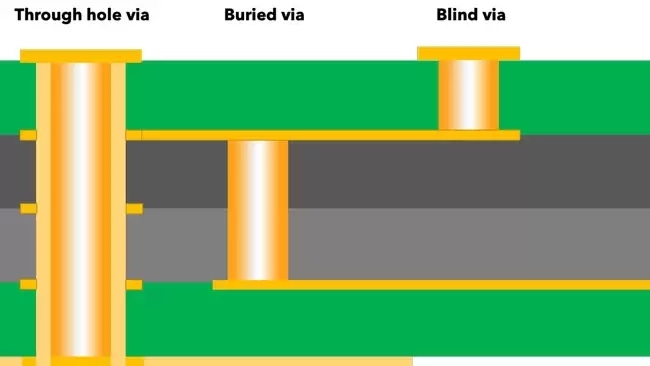

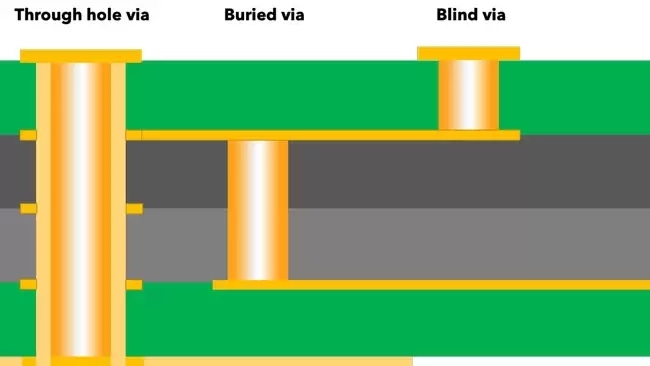

In order to trace such a small circuit board, I had to switch to 4-layer design for the first time. Furthermore, it was not enough just to use 4 layers; I had to use a special feature – such as blind/buried vias. In electronics, via is an electrical connection between layers in the form of a hole with metal-plated walls. In 2-layer circuit boards, vias are drilled through the whole board. For circuit boards with more layers, it is often necessary to connect only selected layers. Blind vias connect outer metal layers with internal ones, while buried vias connect only internal layers:

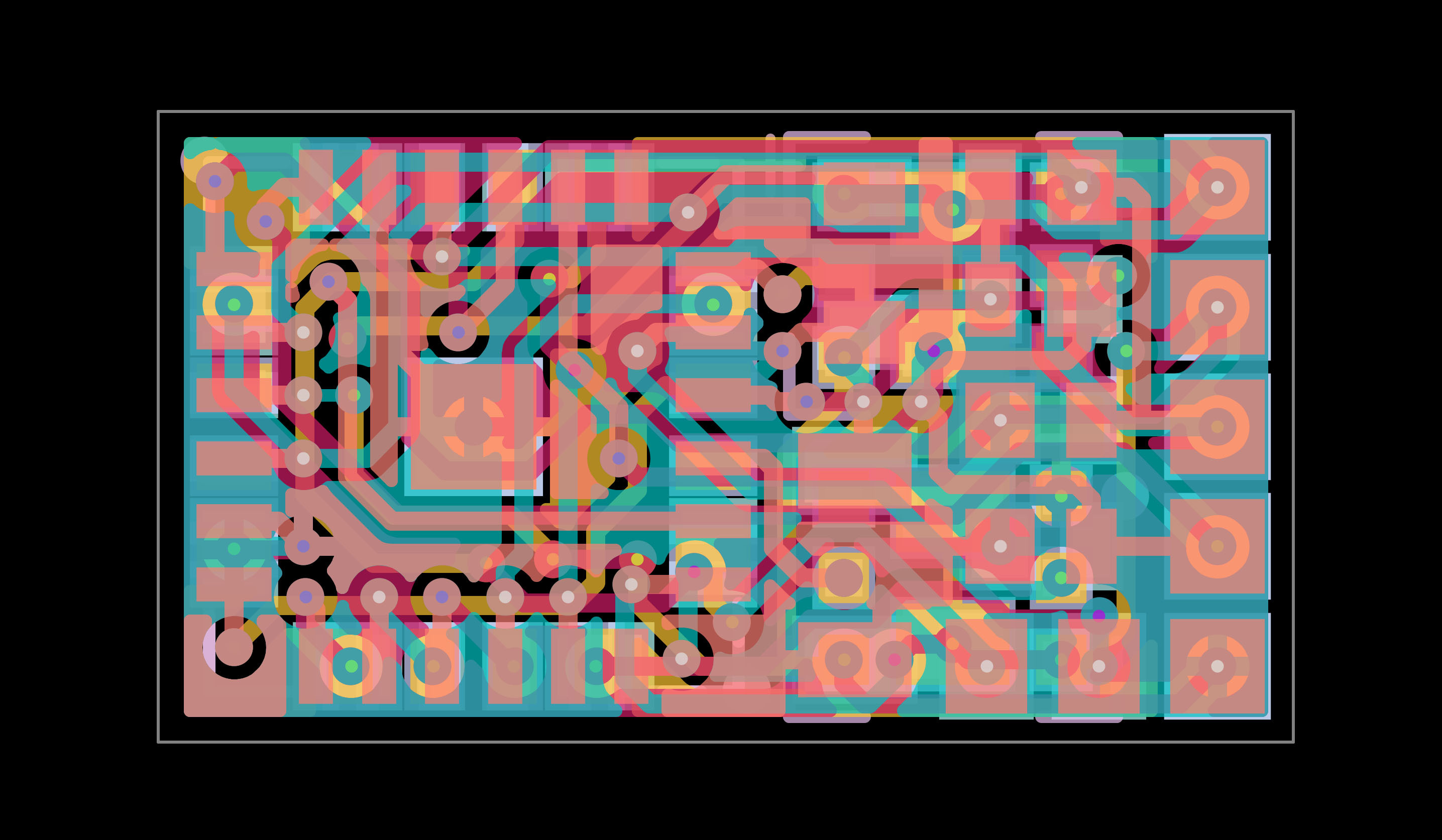

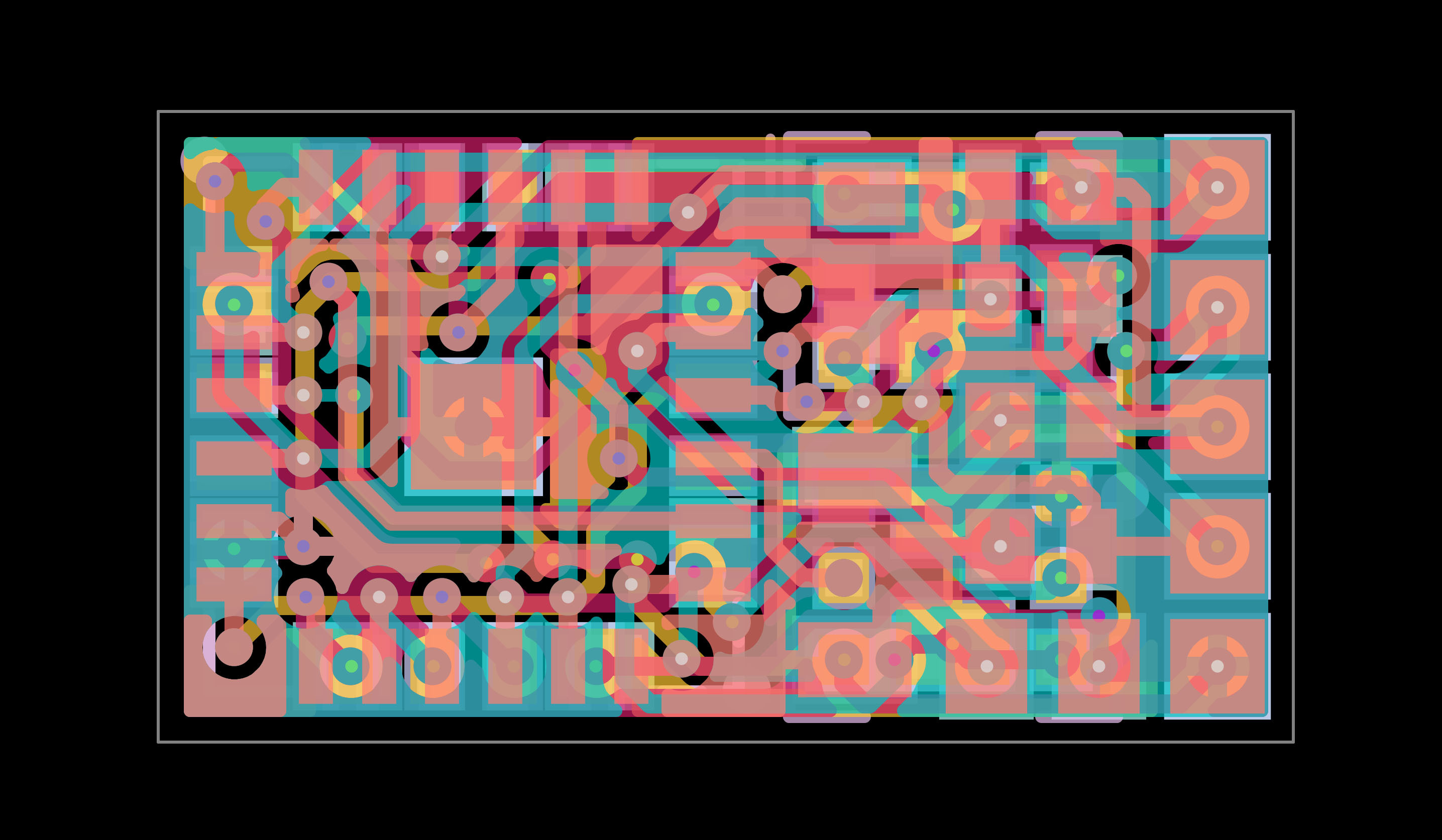

Using blind/buried vias increases the PCB manufacturing price significantly, but it was surely worth it, as I would simply not be able to design such a small circuit board without this technology. Even with all these measures, it was too complex for the PCB software to finish automatic tracing process, so I completed it later manually. Here you can see how complex the tracing of such a small circuit board indeed is. What is seen from the outside does not give an idea of this:

It is important to maintain highest possible width of traces in order to increase current load capability of the device. Thorough manual editing of traces allowed me to increase the total load capacity of the digital decoder to 0.5A.

In order to further reduce the thickness of the digital decoder as much as possible, I needed to achieve a very low thickness of the circuit board. It is not very easy with 4 layers. Nevertheless, I used only 0.1 mm thickness for each layer. As a result, I achieved a total thickness of the circuit board of only 0.45 mm.

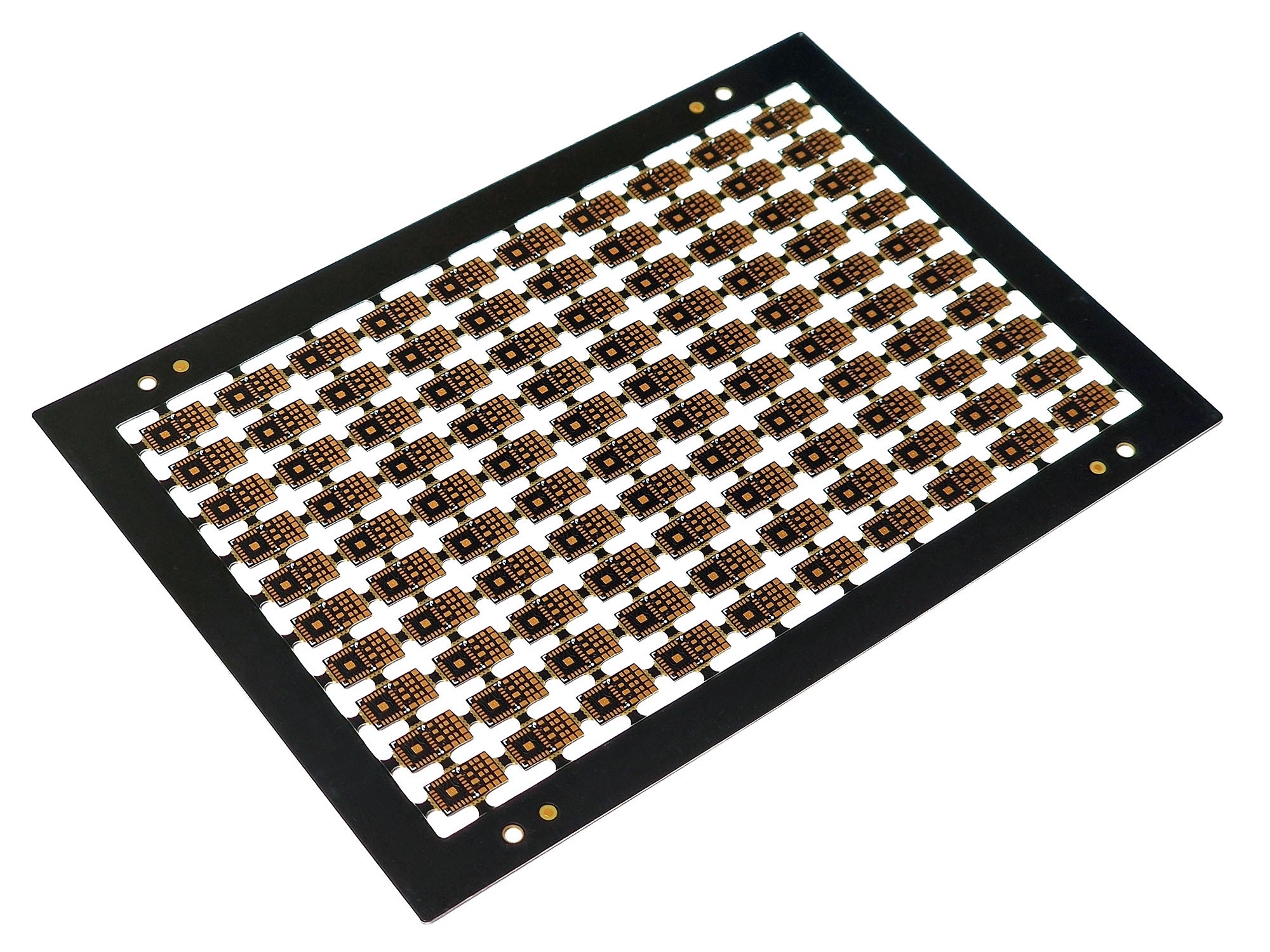

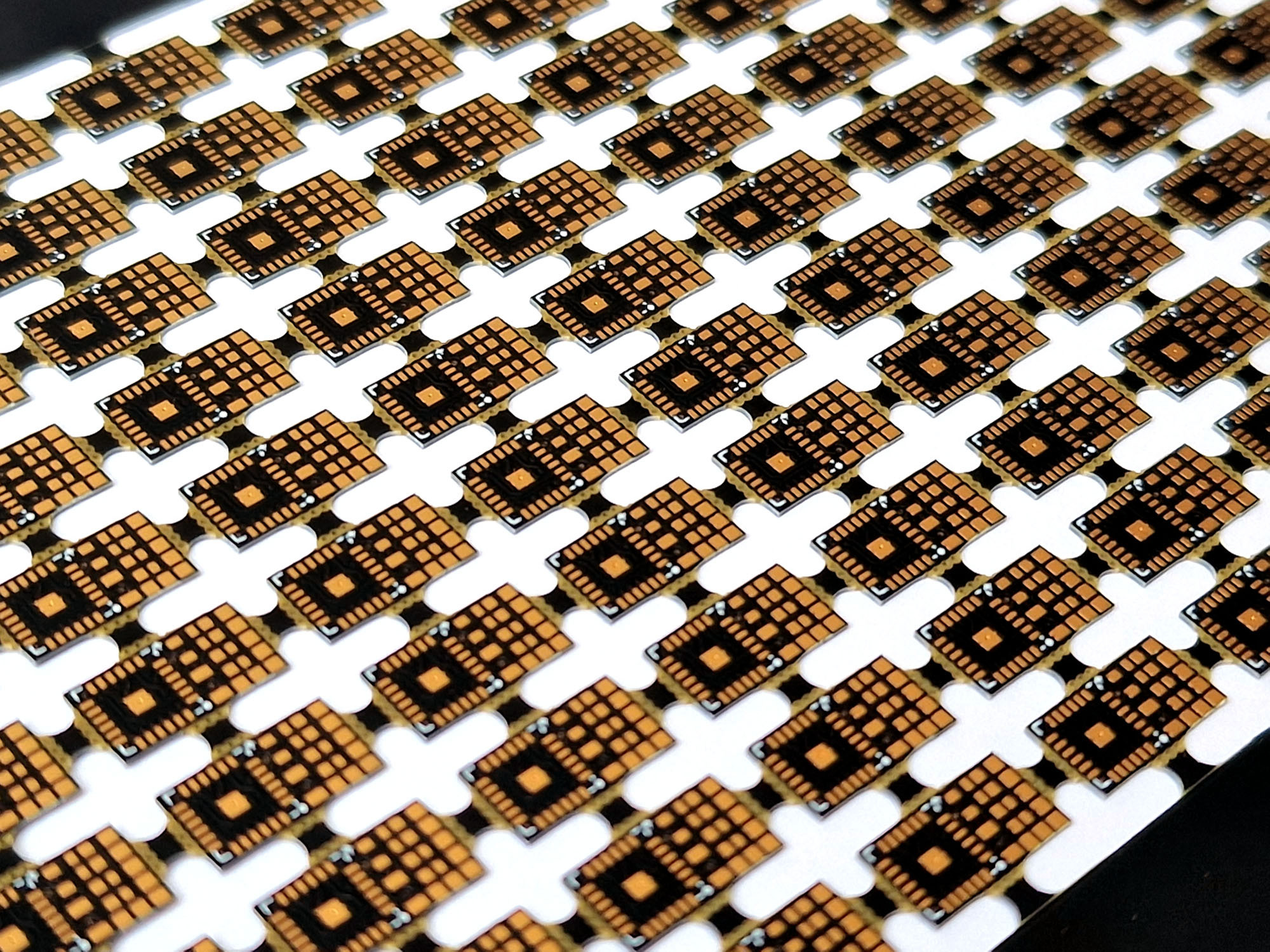

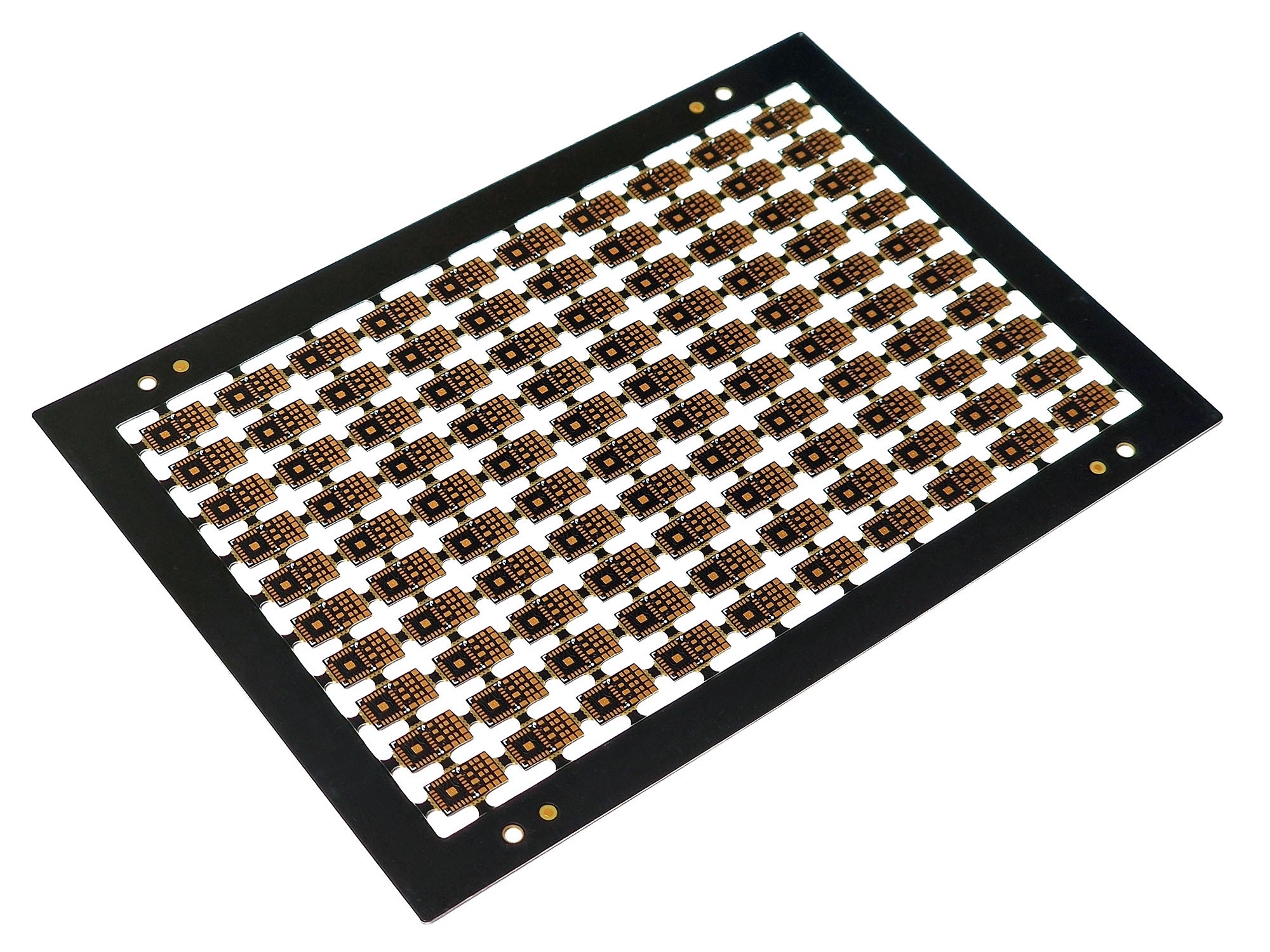

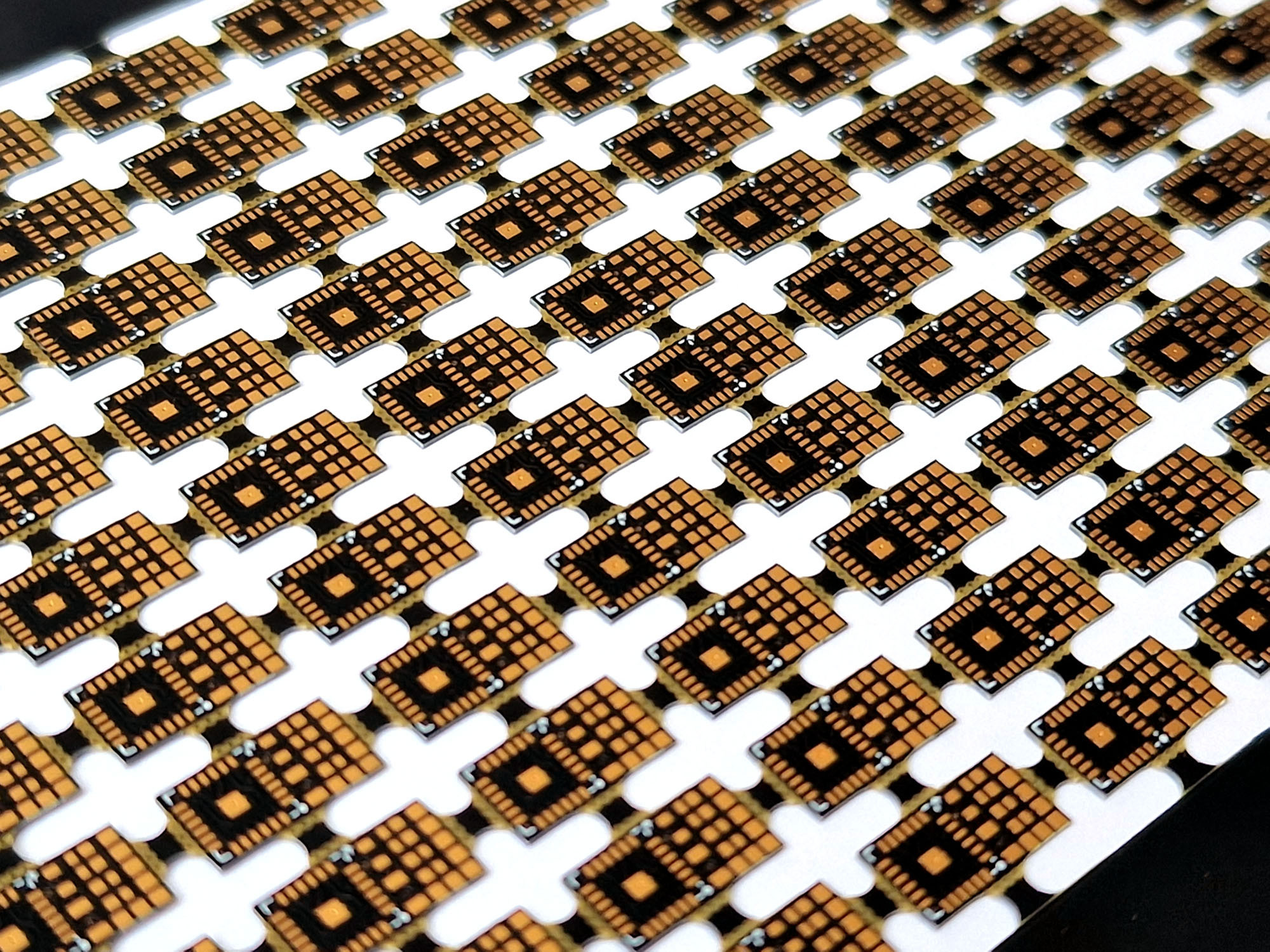

Overall thickness of my digital decoder is only 2 mm. For comparison, D&H PD05A is 2.5 mm thick. 0.5 mm difference is often crucial in some cases with Z scale. Despite small thickness of the material, the circuit board is strong enough – I am very satisfied with the quality delivered by the PCB manufacturer. Of course, the board is gold-plated and lead-free:

So, this is my first HDI circuit board (high-density interconnect). HDI circuit boards are the separate class that usually feature the following properties:

- 4 or more layers;

- Blind/buried vias;

- Vias in pads;

- Very thin traces;

- Smaller components and tighter spacing;

- Electronic components on both sides of the circuit board.

All this is used in ZM05A circuit board and allows it to be as small as it is. The size of my digital decoder is only 9 x 5 x 2 mm. The total volume is only 90 mm3, which allows me to claim that it is the smallest digital decoder in the world currently on the market. For comparison, D&H PD05A has a total volume of 104 mm3, and closest competitor, Zimo MX615 has a volume of 93.5 mm3. Of course, CT Elektronik decoders mentioned above offered smaller sizes, but they have been already gone away.

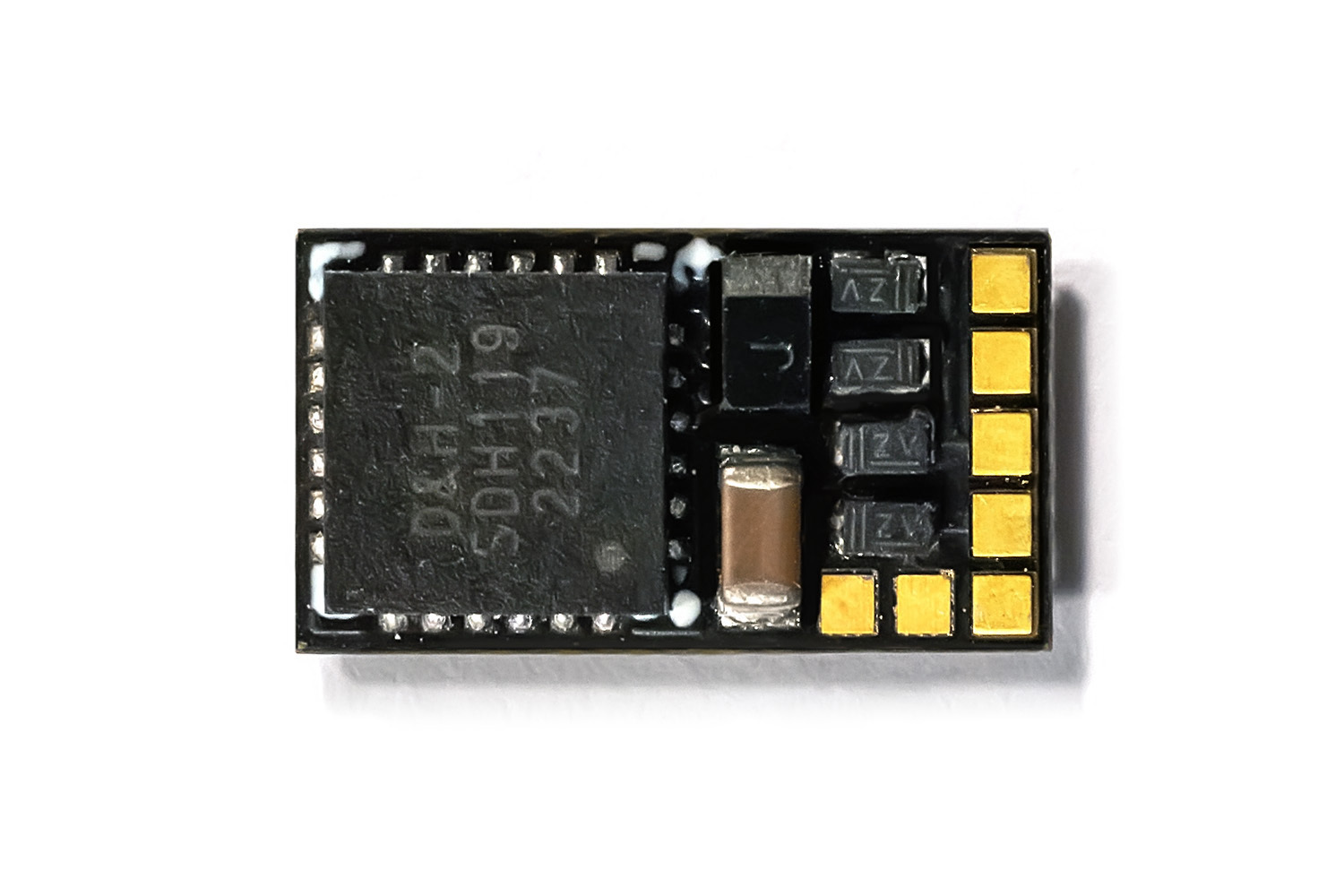

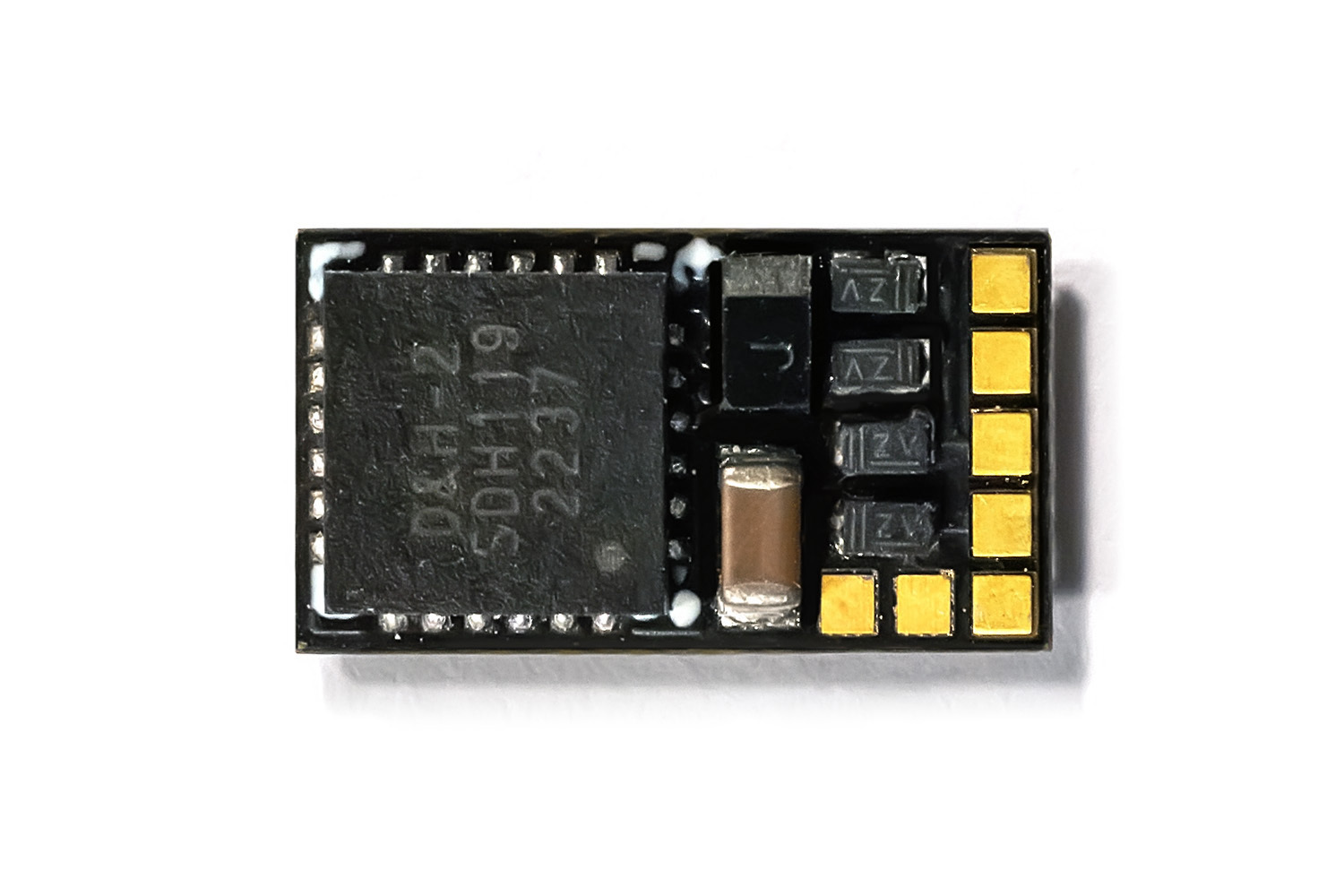

Here is it - digital decoder ZM05A. Top side:

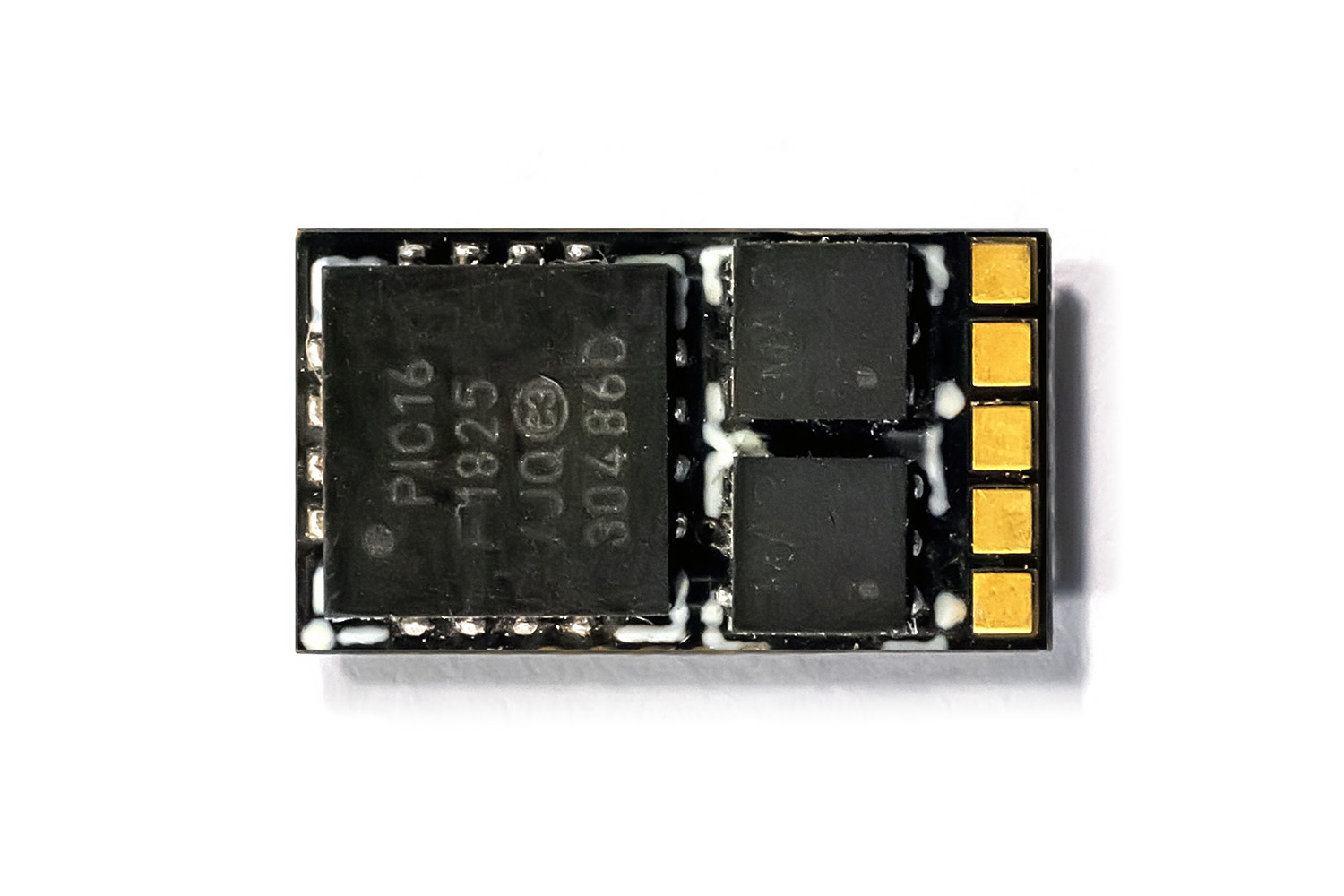

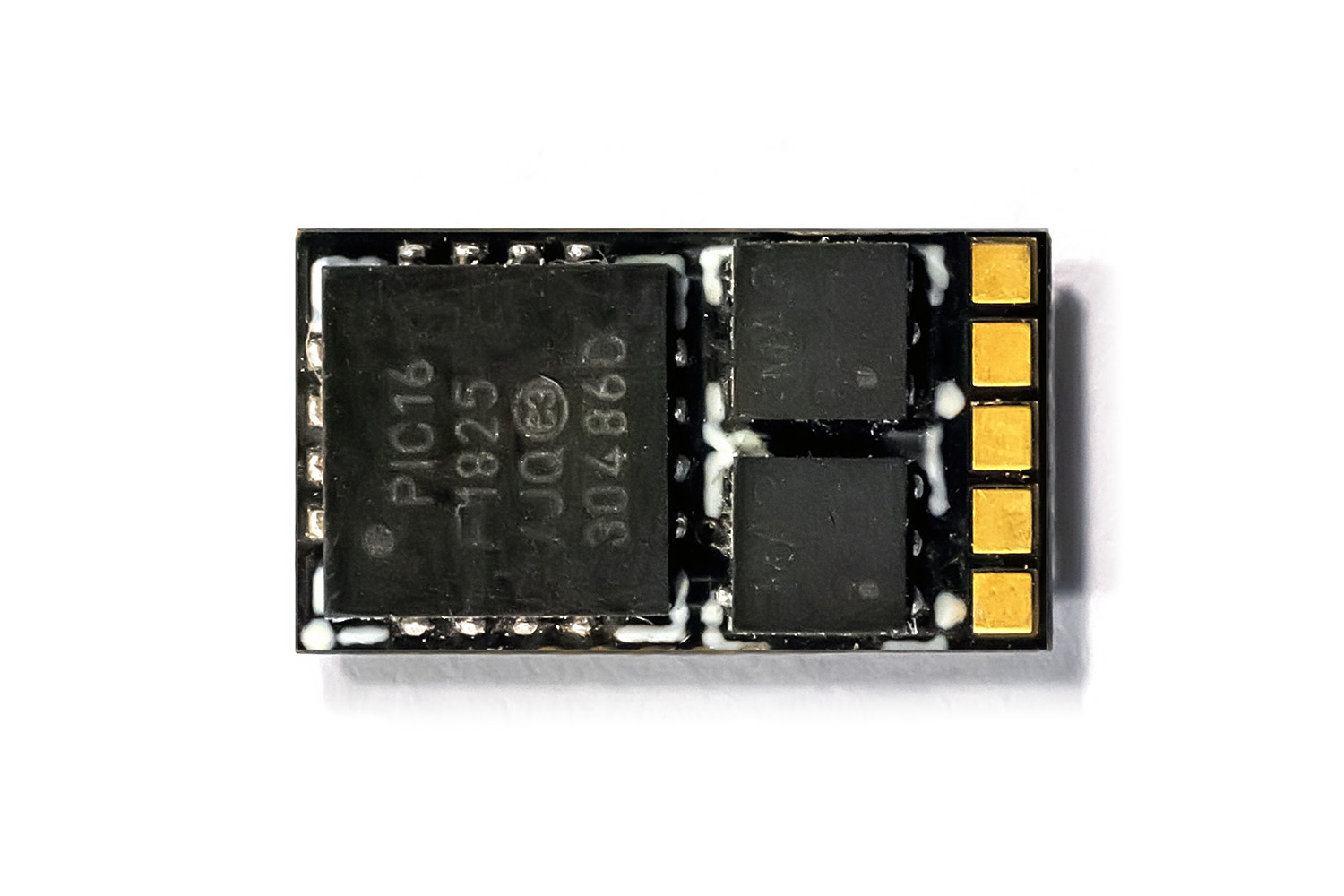

Bottom side:

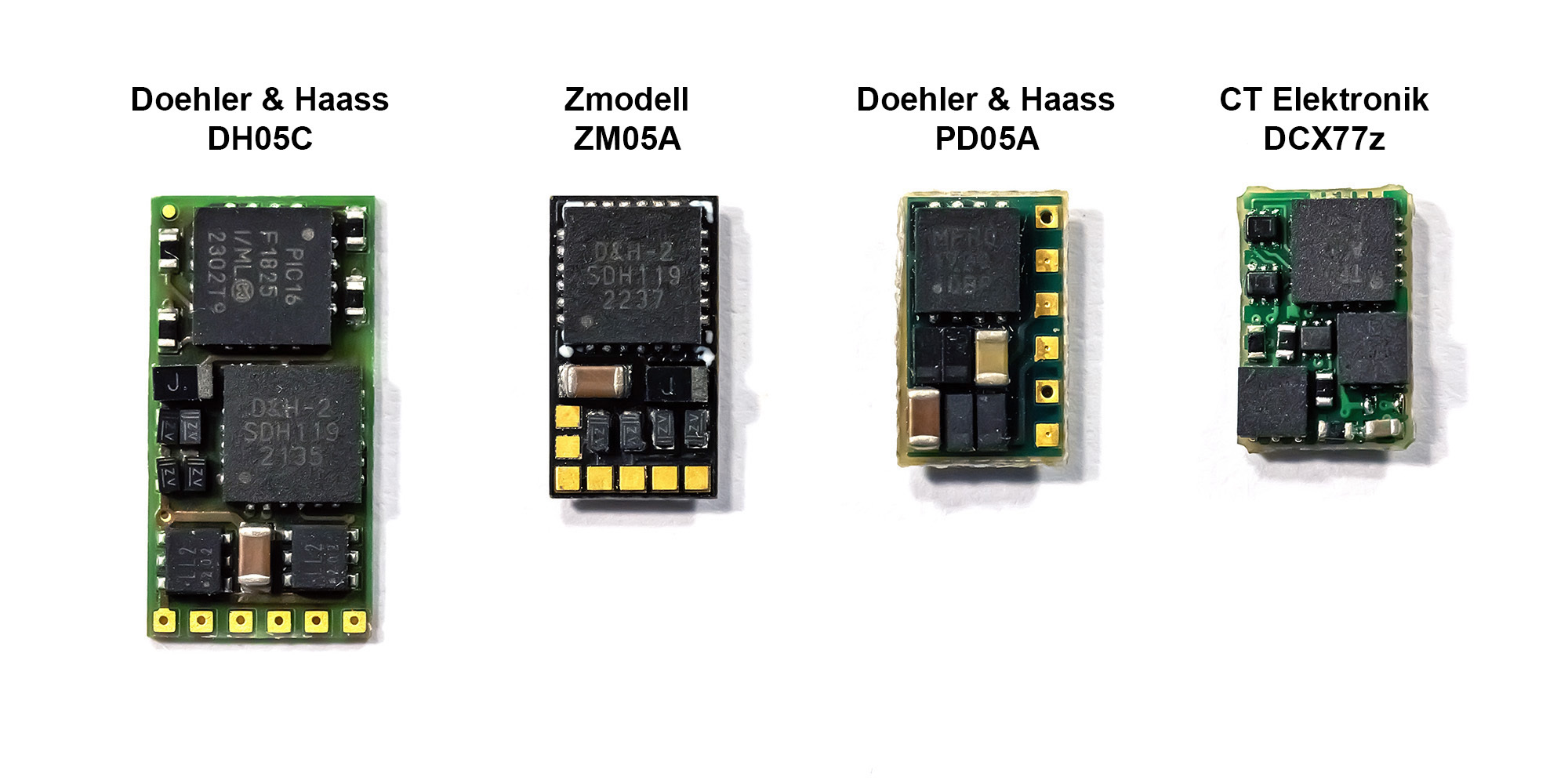

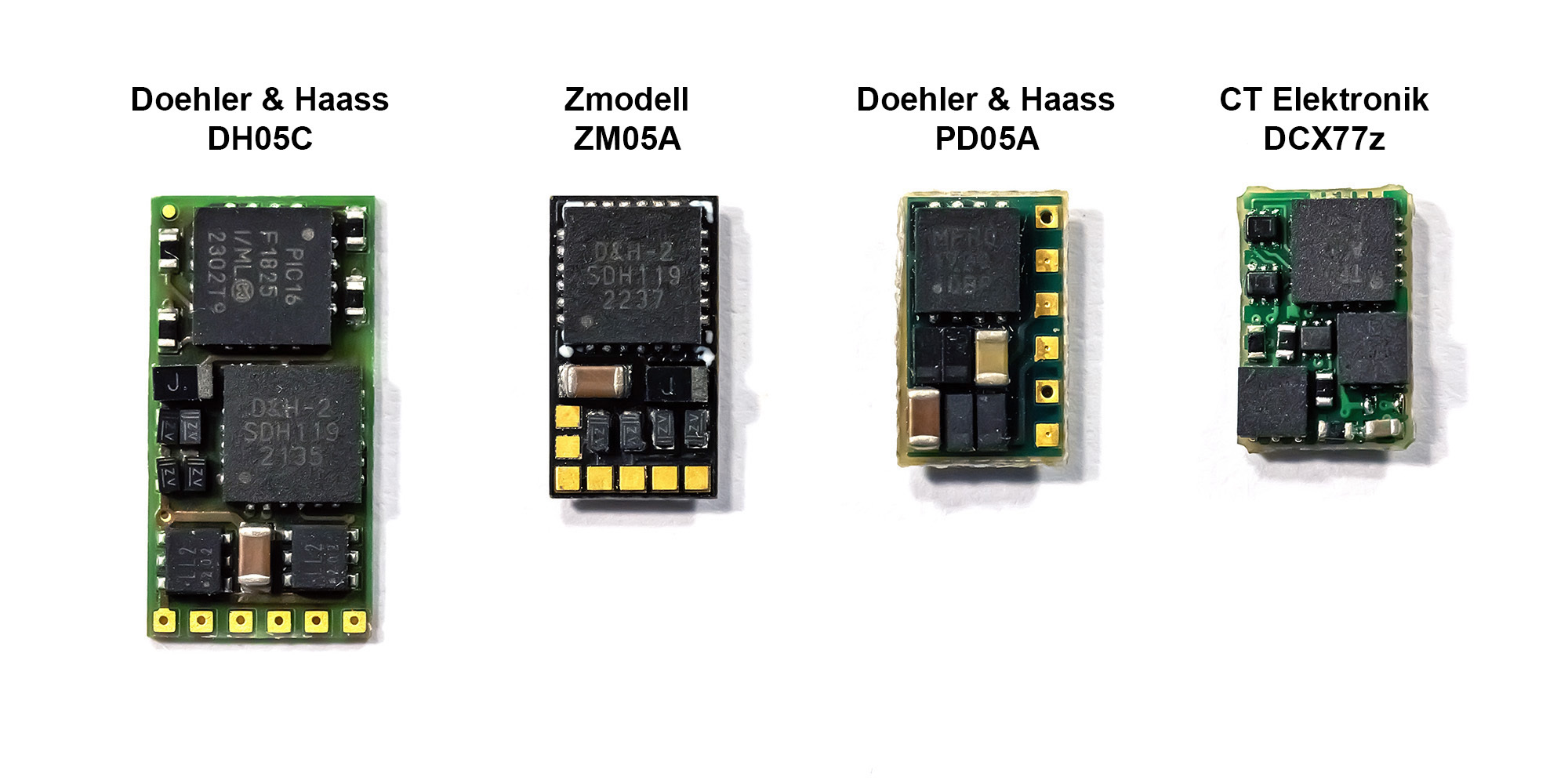

Here is a size comparison – Doehler & Haass DH05C (12.9 x 6.7 x 1.4 mm), Zmodell ZM05A (9 x 5 x 2 mm), Doehler & Haass PD05A (5.2 x 8.0 x 2.5 mm), CT Elektronik DCX77z (5 x 7.6 x 1.8 mm):

In terms of functions and features, ZM05A is identical to D&H DH05C decoder only except ZCLK/AUX5 and ZDAT/AUX6 outputs presented in the last one. All software features like extended function mapping, conditions and of course, analog mode and everything else is here at hands.

I successfully overcame one more limitation of D&H PD05A and packed my decoder with the maximum possible number of outputs. Along with standard track, motor and light connections, my decoder also features amplified AUX1, AUX2 and even two non-amplified AUX3 and AUX4 outputs. Furthermore, there are GND and VS outputs as well. The last two outputs are very important as common wires for light and AUX functions, and also for connecting external energy storage module. Of course, physical arrangement of soldering pads is not compatible with NEM 651 standard, but the main area of usage – digitizing small Z scale locomotives, makes it not so important.

I have also slightly modified default settings of the firmware and optimized it for coreless motors, since the main area of usage is new Z scale locomotives equipped with small coreless motors.

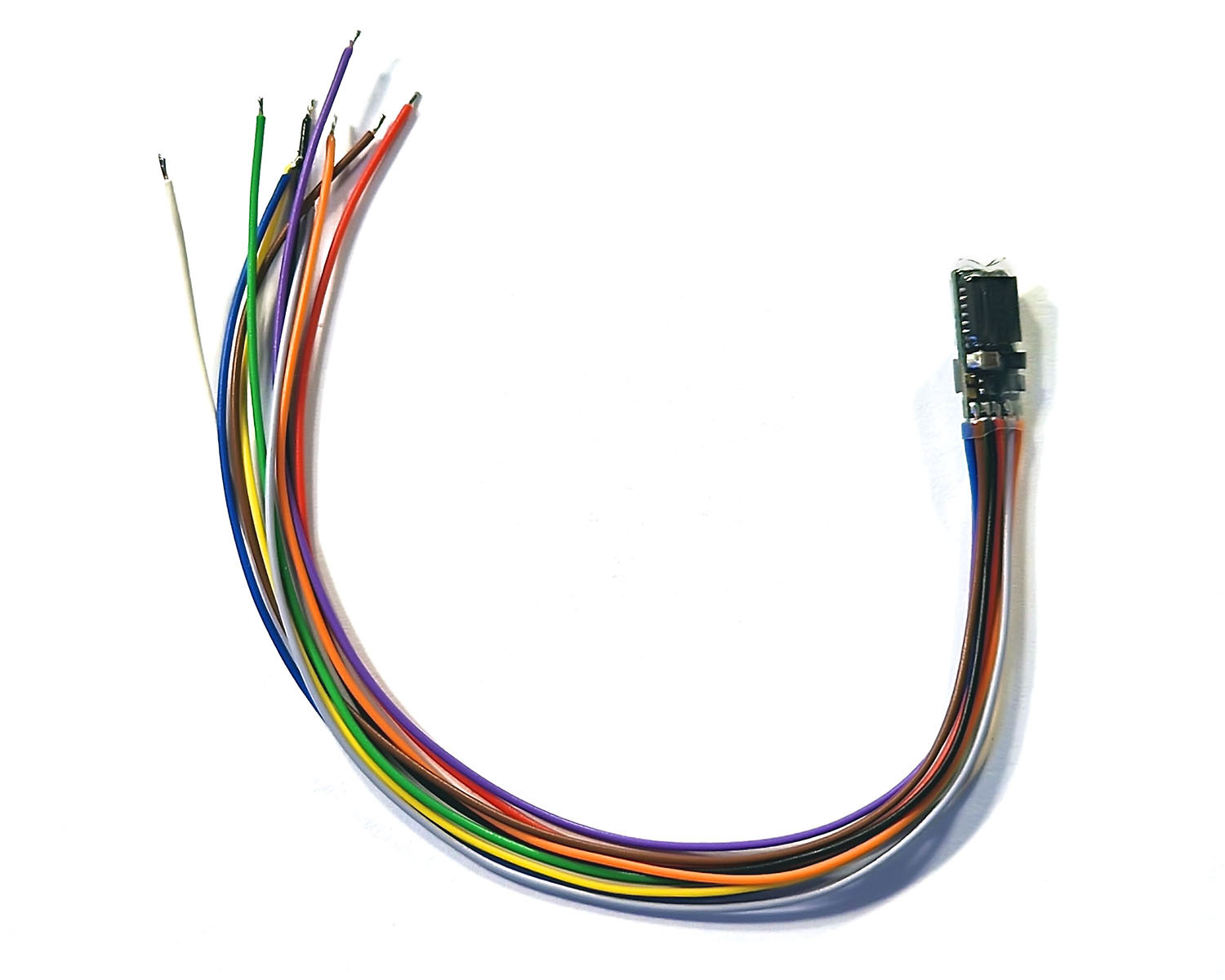

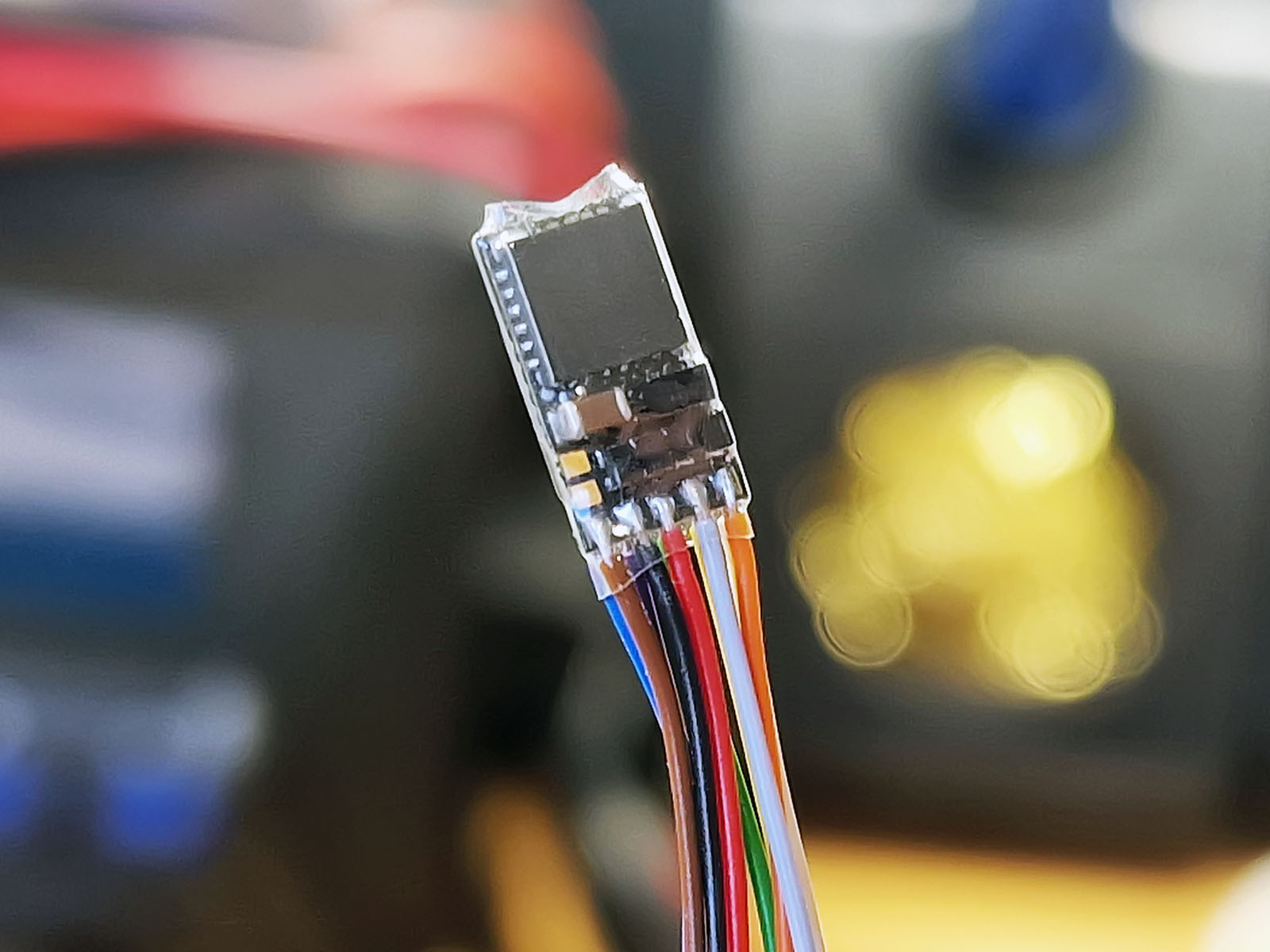

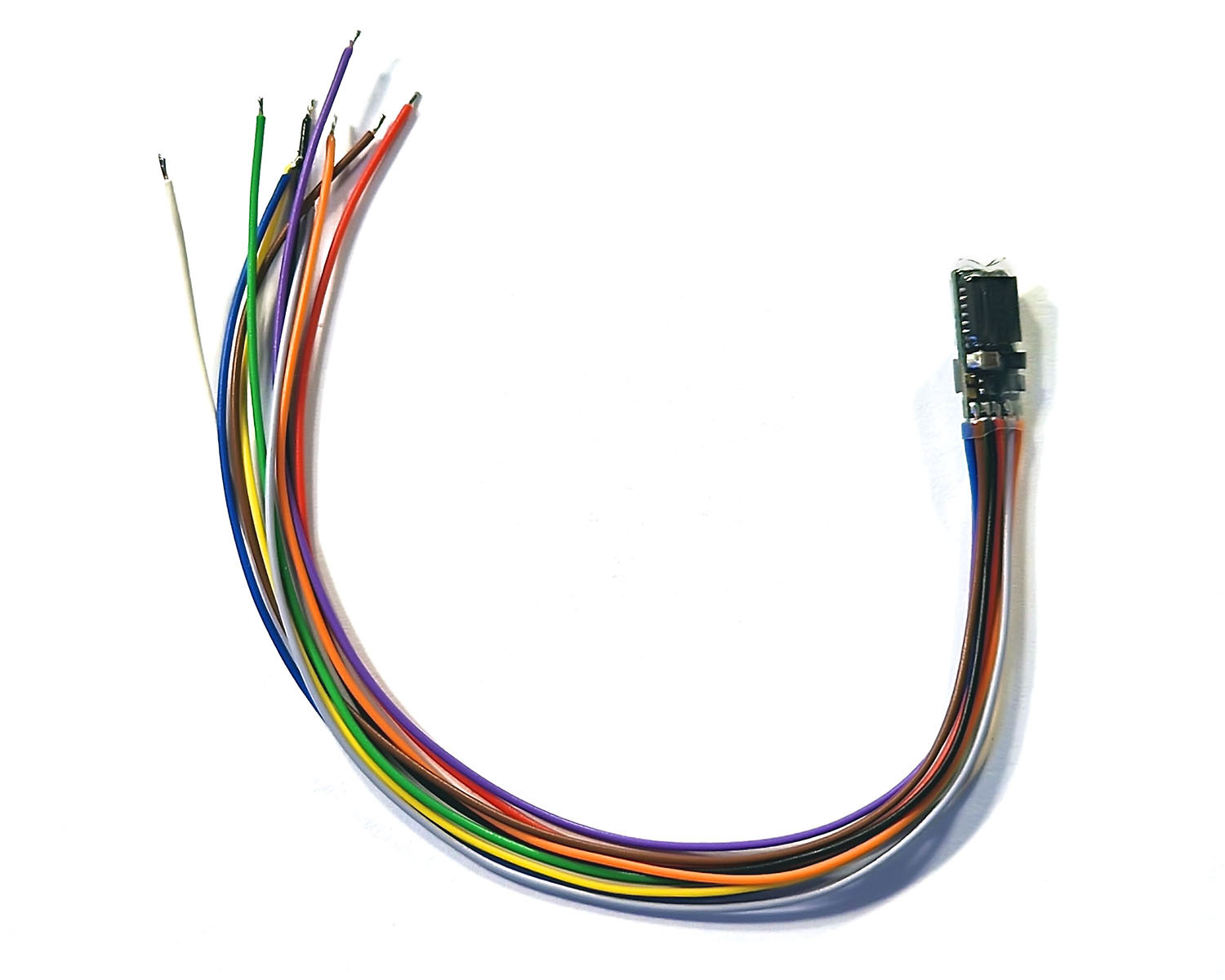

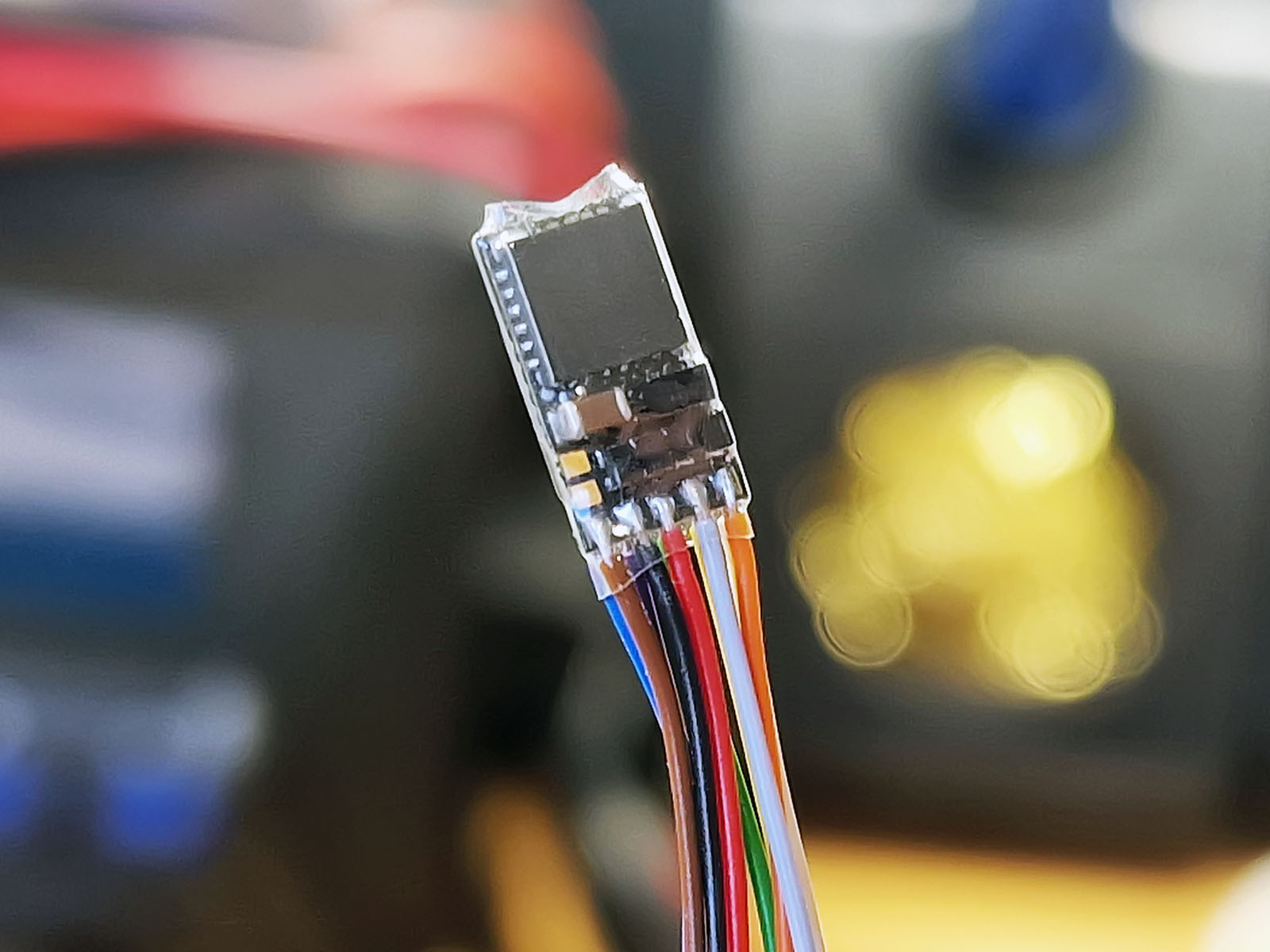

I prepared two variants: without wires and with 10 thin stranded color cables – track, motor, light, AUX1, AUX2, GND and VS. Version with wires is additionally sealed with thin shrinking tube (not a conventional shrinking tube, but with the type that is often used for sealing Lithium rechargeable batteries; it is much thinner):

The main purpose of this development was to digitize small Z scale locomotives from my own collection with something that has no limitations like PD05A. Nevertheless, I thought it would be a good idea to offer this digital decoder to others too.

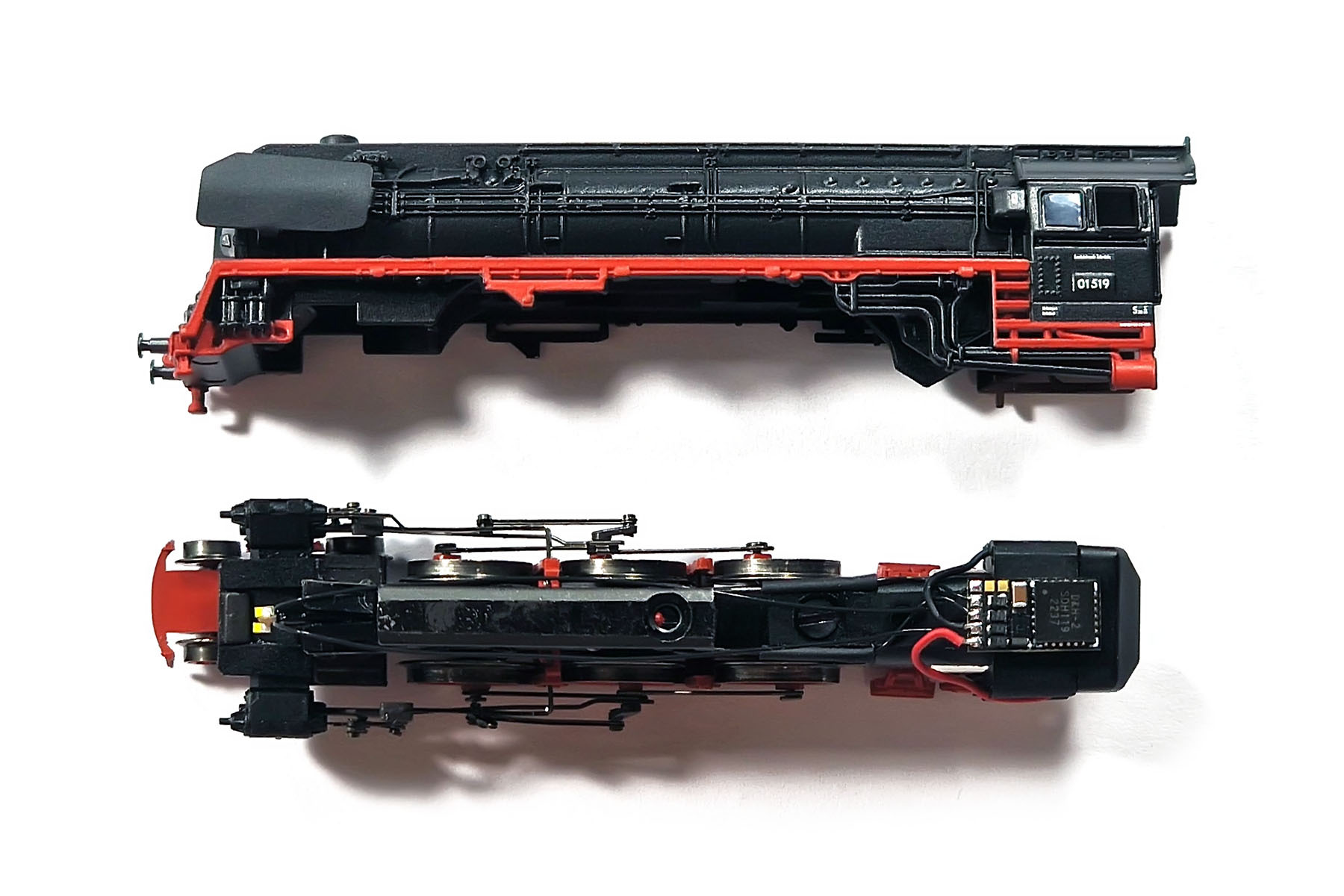

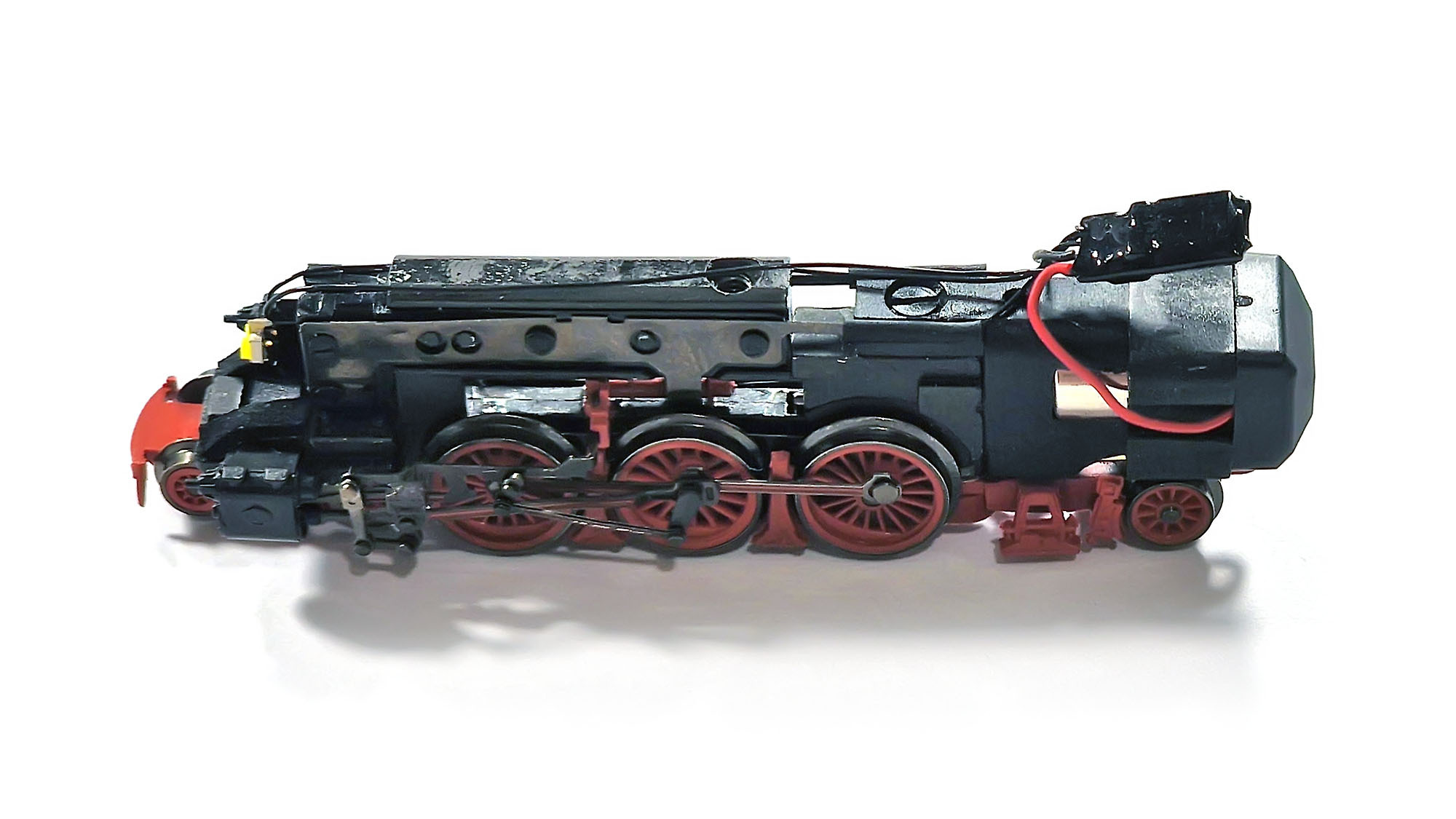

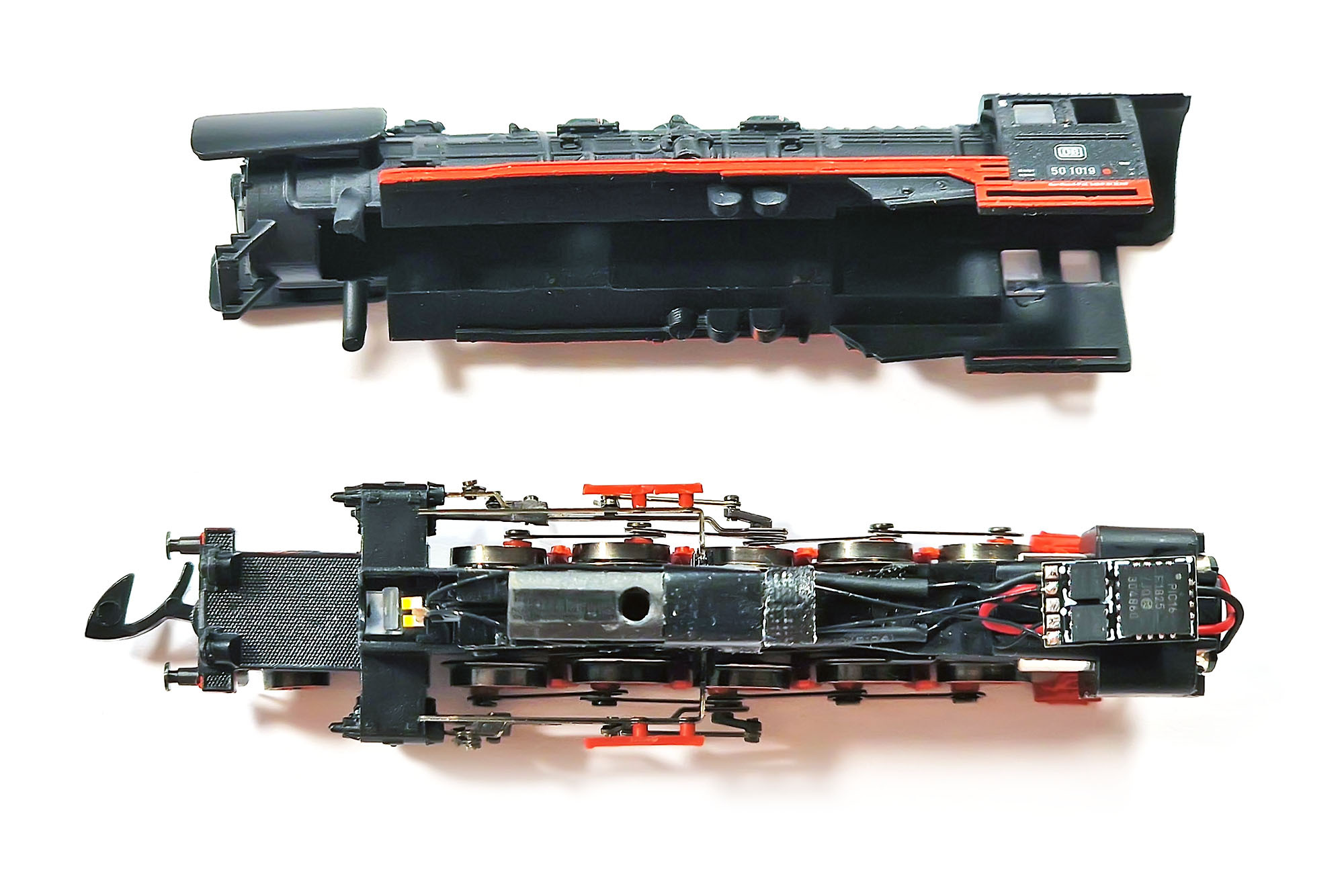

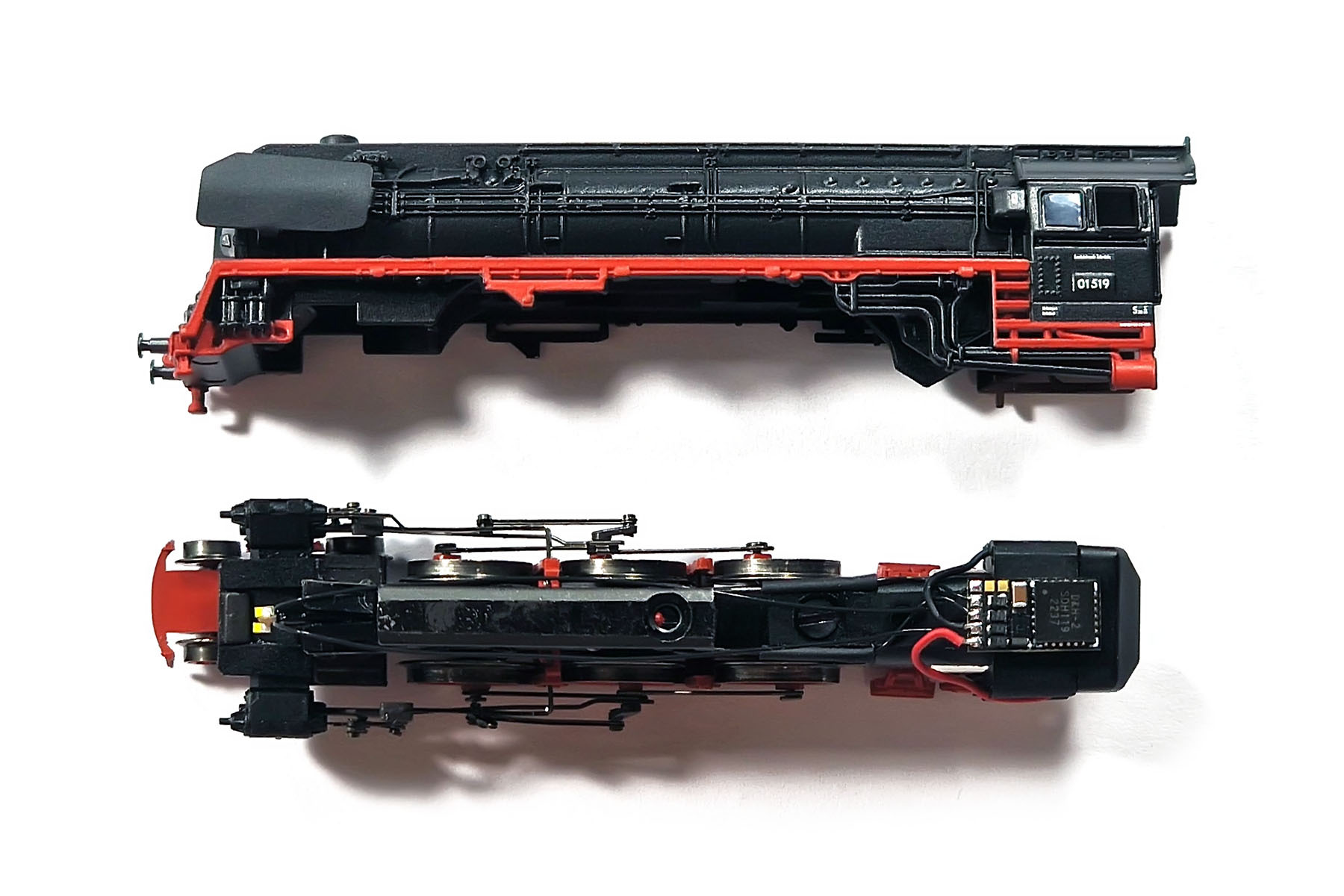

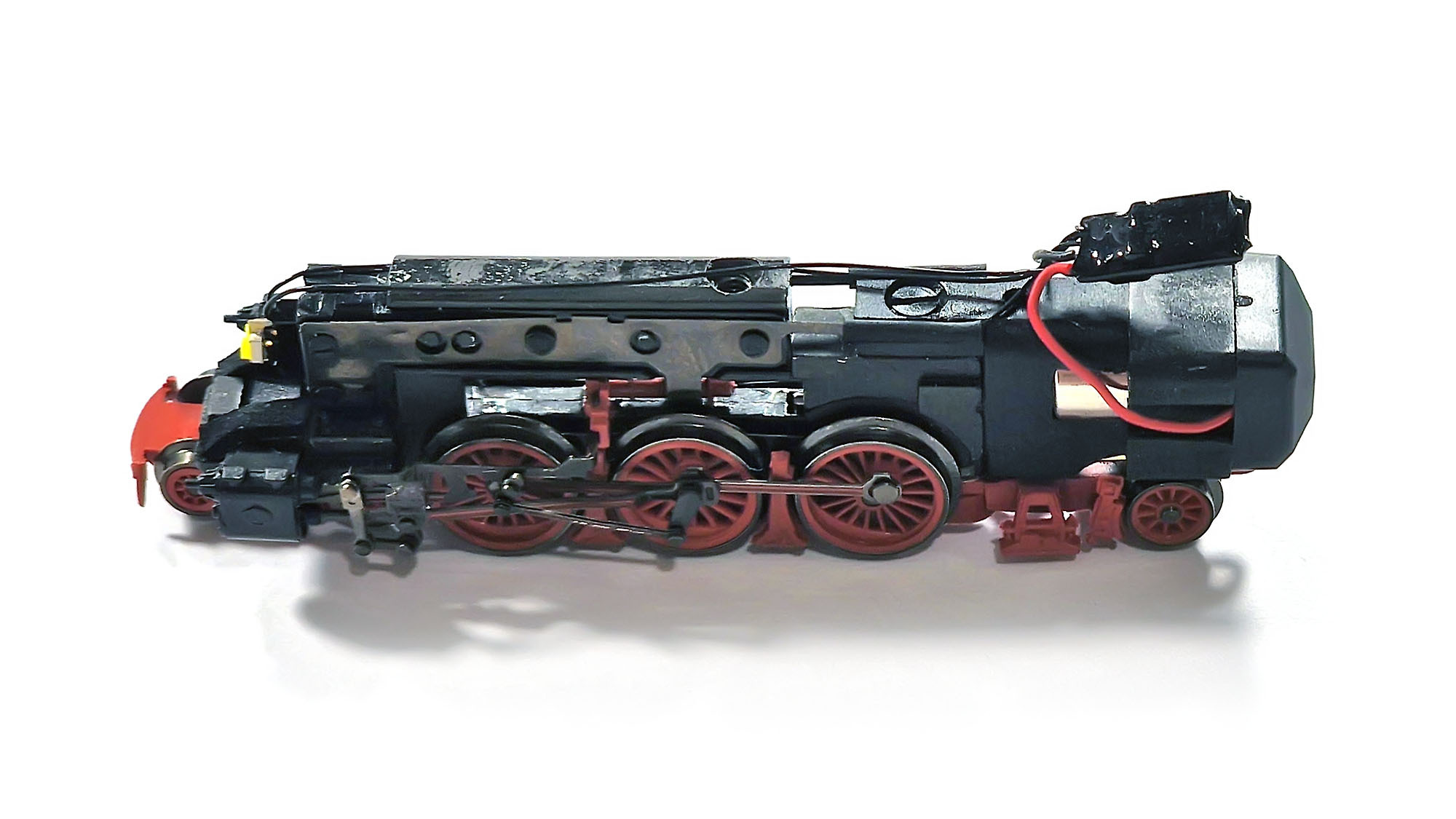

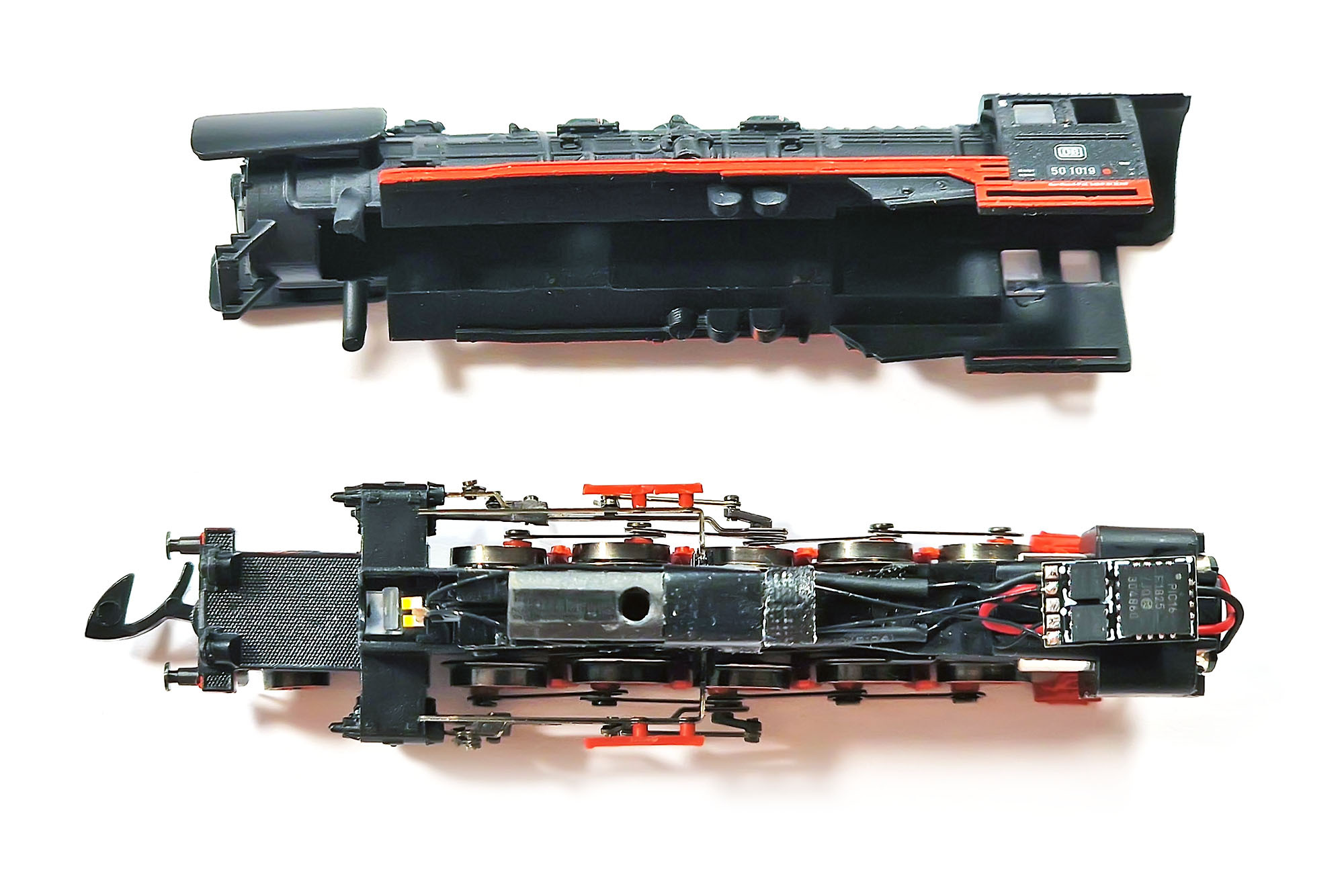

To test the new development, I already successfully digitized two new locomotives in my own collection – BR 01 519 steam locomotive (Märklin 88019) and new variant of BR 50 steamer (Märklin 88846):

ZM05A decoders fitted very easily between the roof and the motor without any problems; they are even barely visible when looking from outside. Everything works flawlessly – just as expected.

I already prepared User's Manual for ZM05A digital decoder. I decided to include into my User's Manual solutions to the most common questions – such as variants of connecting lights, buffering capacitors, and so on. It can be downloaded here:

ZM05A.PDF

Best regards,

Alex

The background of this development was the fact that I was not satisfied with the limitations of small Doehler & Haass PD05A digital decoder which lack some crucial features presented in the next small decoder DH05C – like supporting analog mode by default, conditions, AUX outputs and some others. Replacing firmware by the one from D&H PD12A seemed to me not to be a convincing solution, as the only thing it did is adding support of analog mode (at the cost of some existing features of PD05A), while all other limitations common to PD series still remained. I admit that Doehler & Haass digital decoders are almost unknown in the USA, but I just thought that these details may be interesting for the whole story.

In the past, I widely used very small CT Elektronik DCX77z decoders for digitizing certain models in Z scale (in particular, steam locomotives which often offer very limited space inside for anything extra), but after CT Elektronik has been vanished from the market, D&H PD05A remained mostly the only possible option for such intricate digitizing projects.

It is also a well-known fact that CT Elektronik decoders were mostly a “wild, nasty and untamed” thing. Furthermore, they were prone to complete failure after a “single breath”. All this together unfortunately made them an unfavorable solution.

After successful development of a number of different digital decoders for Z scale locomotives (such as AZL SW1500, Märklin DB V80, VT98, SBB Ce 6/8 III and DB V188) using proven Doehler & Haass technology, and also using a different modification of microcontroller with reduced thickness (0.5 mm against 0.9 mm) in my digital decoder for Märklin DB V80 locomotive, I came up with an idea to develop an alternative to PD05A which would have nearly the same size, but no functional limitations at all. I decided to use 2-sided design and to populate all thinnest electronic components on one side of the circuit board and everything else on another.

In order to trace such a small circuit board, I had to switch to 4-layer design for the first time. Furthermore, it was not enough just to use 4 layers; I had to use a special feature – such as blind/buried vias. In electronics, via is an electrical connection between layers in the form of a hole with metal-plated walls. In 2-layer circuit boards, vias are drilled through the whole board. For circuit boards with more layers, it is often necessary to connect only selected layers. Blind vias connect outer metal layers with internal ones, while buried vias connect only internal layers:

Using blind/buried vias increases the PCB manufacturing price significantly, but it was surely worth it, as I would simply not be able to design such a small circuit board without this technology. Even with all these measures, it was too complex for the PCB software to finish automatic tracing process, so I completed it later manually. Here you can see how complex the tracing of such a small circuit board indeed is. What is seen from the outside does not give an idea of this:

It is important to maintain highest possible width of traces in order to increase current load capability of the device. Thorough manual editing of traces allowed me to increase the total load capacity of the digital decoder to 0.5A.

In order to further reduce the thickness of the digital decoder as much as possible, I needed to achieve a very low thickness of the circuit board. It is not very easy with 4 layers. Nevertheless, I used only 0.1 mm thickness for each layer. As a result, I achieved a total thickness of the circuit board of only 0.45 mm.

Overall thickness of my digital decoder is only 2 mm. For comparison, D&H PD05A is 2.5 mm thick. 0.5 mm difference is often crucial in some cases with Z scale. Despite small thickness of the material, the circuit board is strong enough – I am very satisfied with the quality delivered by the PCB manufacturer. Of course, the board is gold-plated and lead-free:

So, this is my first HDI circuit board (high-density interconnect). HDI circuit boards are the separate class that usually feature the following properties:

- 4 or more layers;

- Blind/buried vias;

- Vias in pads;

- Very thin traces;

- Smaller components and tighter spacing;

- Electronic components on both sides of the circuit board.

All this is used in ZM05A circuit board and allows it to be as small as it is. The size of my digital decoder is only 9 x 5 x 2 mm. The total volume is only 90 mm3, which allows me to claim that it is the smallest digital decoder in the world currently on the market. For comparison, D&H PD05A has a total volume of 104 mm3, and closest competitor, Zimo MX615 has a volume of 93.5 mm3. Of course, CT Elektronik decoders mentioned above offered smaller sizes, but they have been already gone away.

Here is it - digital decoder ZM05A. Top side:

Bottom side:

Here is a size comparison – Doehler & Haass DH05C (12.9 x 6.7 x 1.4 mm), Zmodell ZM05A (9 x 5 x 2 mm), Doehler & Haass PD05A (5.2 x 8.0 x 2.5 mm), CT Elektronik DCX77z (5 x 7.6 x 1.8 mm):

In terms of functions and features, ZM05A is identical to D&H DH05C decoder only except ZCLK/AUX5 and ZDAT/AUX6 outputs presented in the last one. All software features like extended function mapping, conditions and of course, analog mode and everything else is here at hands.

I successfully overcame one more limitation of D&H PD05A and packed my decoder with the maximum possible number of outputs. Along with standard track, motor and light connections, my decoder also features amplified AUX1, AUX2 and even two non-amplified AUX3 and AUX4 outputs. Furthermore, there are GND and VS outputs as well. The last two outputs are very important as common wires for light and AUX functions, and also for connecting external energy storage module. Of course, physical arrangement of soldering pads is not compatible with NEM 651 standard, but the main area of usage – digitizing small Z scale locomotives, makes it not so important.

I have also slightly modified default settings of the firmware and optimized it for coreless motors, since the main area of usage is new Z scale locomotives equipped with small coreless motors.

I prepared two variants: without wires and with 10 thin stranded color cables – track, motor, light, AUX1, AUX2, GND and VS. Version with wires is additionally sealed with thin shrinking tube (not a conventional shrinking tube, but with the type that is often used for sealing Lithium rechargeable batteries; it is much thinner):

The main purpose of this development was to digitize small Z scale locomotives from my own collection with something that has no limitations like PD05A. Nevertheless, I thought it would be a good idea to offer this digital decoder to others too.

To test the new development, I already successfully digitized two new locomotives in my own collection – BR 01 519 steam locomotive (Märklin 88019) and new variant of BR 50 steamer (Märklin 88846):

ZM05A decoders fitted very easily between the roof and the motor without any problems; they are even barely visible when looking from outside. Everything works flawlessly – just as expected.

I already prepared User's Manual for ZM05A digital decoder. I decided to include into my User's Manual solutions to the most common questions – such as variants of connecting lights, buffering capacitors, and so on. It can be downloaded here:

ZM05A.PDF

Best regards,

Alex